We help the world growing since 2004

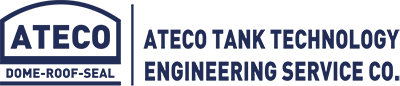

Bend Master Roof Drain Joint

- Home

- Bend Master Roof Drain Joint

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4280

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379Bend Master Roof Drain Joint

Bend Master Roof Drain Joint

ATECO Drain Systems offer proven technology, maintenance -free, easy to install floating roof drains. All you need to do is fill in and fax to us our standard ATECO Tank Drain Data Sheet and we will provide installation drawings for you. The ATECO Drain System is easy to install in any tank. Each drain line requires just a 500mm wide corridor to operate in, between sump and shell nozzles. In tanks above 60m diameter, it is advisable for safety reasons, to fit more than one drain. This can easily be done with the ATECO Drain System. As many as 5 lines have previously been fitted to one large crude oil storage tank.

| [rtbs name=”bend-master-roof-drain-joint”] |

|

|---|

: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66