We help the world growing since 2004

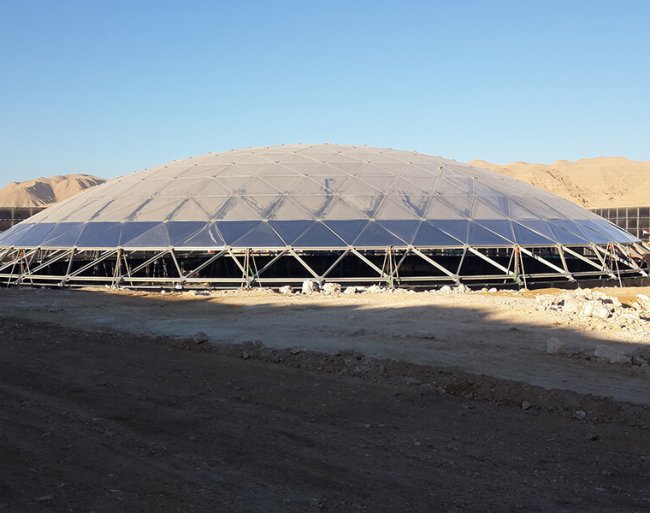

Aluminum Geodesic Dome Roofs

- Home

- Aluminum Geodesic Dome Roofs

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4280

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379Aluminum Geodesic Dome Roofs

Geodesic Dome Roofs

ATECO specializes in the design, manufacturing, supply and installing of above ground storage tank equıpment. The management of ATECO has an extensive track record in this industry, therefore we are the experts in servicing your requirements in this area.

Geodesic aluminum domes are the preferred cover solution for any storage application. Aluminum dome structures are superior to other cover designs due to alternate materials due to:

| [rtbs name=”geodesic-dome-roof”] |

|

: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66